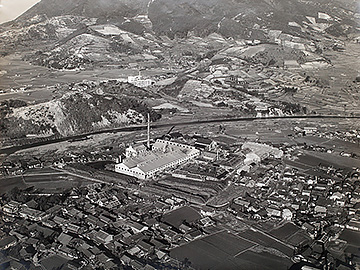

Kinsei Mill

The dawn of papermaking in Shikokuchuo City is said to date back to around 1750-60. Thanks to the rich water sources and native plants such as mitsumata and kozo that grow in the valleys of Hoo mountain range that run to the south of the city, the popularity of papermaking spread as an auxiliary business for local farmers. The area has long been an important transportation hub within the Shikoku region and has made great strides to become one of the major paper production regions in Japan today.

Marusumi Paper Company made its start at what is now Kinsei Mill in 1919 with Japanese handmade paper. While the papermaking machines were removed from this site in the late 1980s, today, our affiliate company Marusumi Engineering Co., Ltd. manufactures paper tubes and conducts paper processing work at this location.

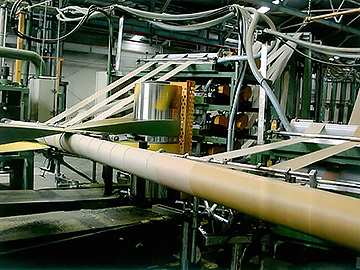

Paper Tube Division

Our paper tubes are constructed of boards called “paper tube base paper” made of used materials such as cardboard, newspaper, and magazines. While paper tubes have a wide variety of uses, those manufactured at Marusumi Engineering are used as the core tube around which the papers manufactured by Marusumi Paper Company are wrapped.

At the Kinsei Mill, we manufacture core tubes using new paper as well as recycled paper.

- Equipment

- Bobbin slitter

Spiral machine (for paper roll manufacturing)

Core tube processing machines (No.1 - No.4)

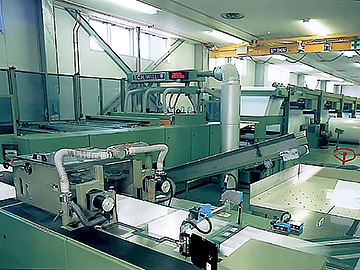

Paper Processing Division

In the paper processing division, rolls of paper manufactured by Marusumi Paper Company are cut into various dimensions according to customers’ needs.

The small-size cutter is used mainly to prepare copy papers, the large-size cutters are to prepare larger flat sheets of paper, and in the slitter processing, the paper is cut to specified sizes.

- Equipment

- Small-size cutter

Large-size cutter No.1, No.2

Large-size automatic wrapping machine, binding machine

Slitter machine No.1, No.2

Manual wind-up wrapping machine