Reducing environmental footprint is a persistent issue for a corporation.

Marusumi Paper Company has succeeded in developing our own proprietary production process for a new next-generation material called cellulose nanofiber (CNF) that is friendly to the environment while being strong durable and lightweight.

What is Cellulose Nanofiber?

Cellulose nanofibers (CNF) are extremely thin cellulose fibers made from wood material. We use our existing papermaking technology to produce wood pulp (material for making paper), which is then micro-refined to the nano-level. Sometimes called nanocellulose, it is a new type of biomass-derived material.

Nanocellulose fibers are as thin as a few nanometers. They are known to have a unique type of viscosity, to be transparent, lightweight, and strong durable, and to change very little in shape due to temperature fluctuations. It is expected to be adapted for uses in a variety of fields.

●Nanometer = one millionth of 1 mm in length

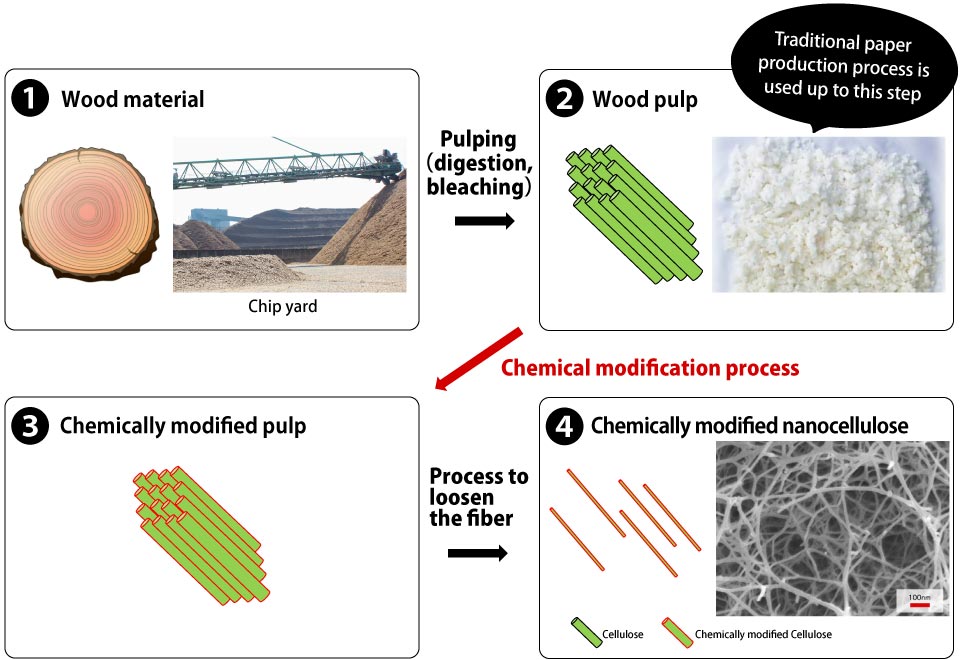

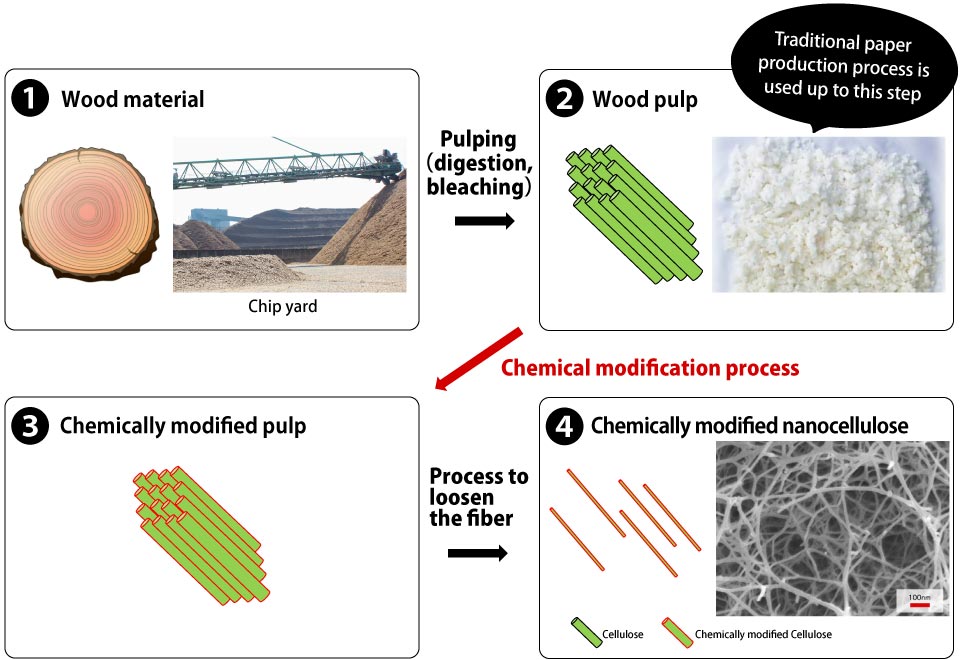

From wood pulp to nanocellulose

- Wood is crushed into woodchips (of about 5cm width and 1cm thickness)

- At the paper mill, fibers are extracted from the woodchips and pulped.

- The pulp is chemically processed so that it can be loosened into thin pieces easily (chemical modification).

- High pressure is applied to loosen the wood fibers (pulp).

Features of nanocellulose

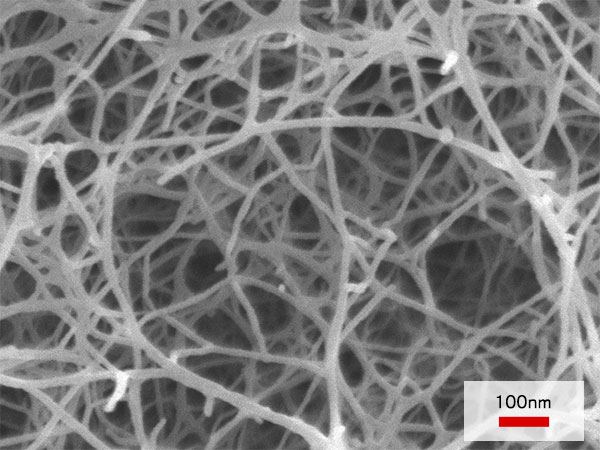

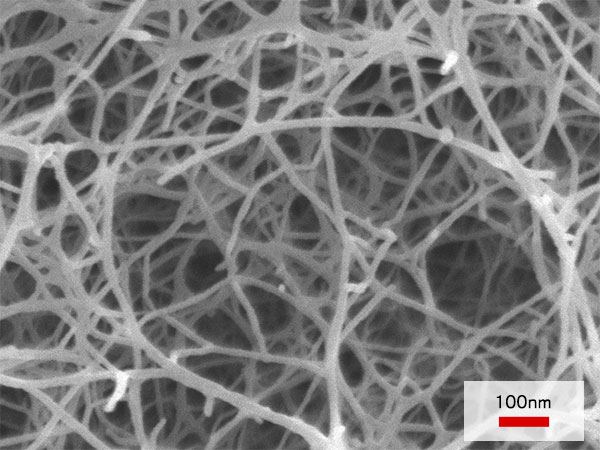

Electron microscope photograph of CNF

Pulp that we have produced (KP) is chemically processed and ionic compound is added to the cellulose of the wood fiber formation. The electrostatic repulsive reaction of this functional compound easily loosens the fiber down to the nano-level, and stably breaks apart into long and thin fibers of a few nanometers.

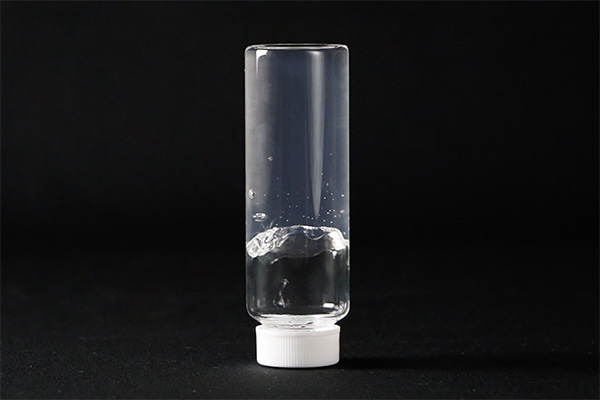

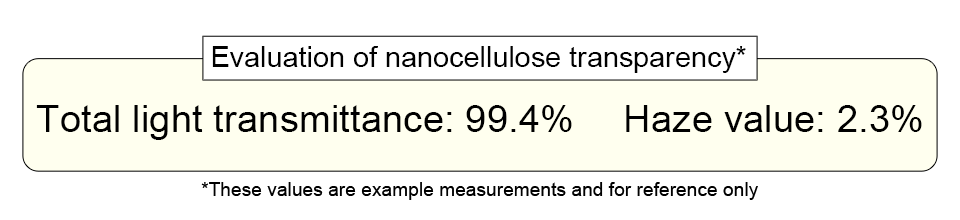

The fibers are now as thin as a few nanometers and are finer than the wavelength of visible light (400nm-700nm). Therefore, the CNF is transparent as light can pass through its fibers.

●KP = kraft pulp, chemical pulp

Features of Marusumi Paper Company’s chemically modified nanocellulose

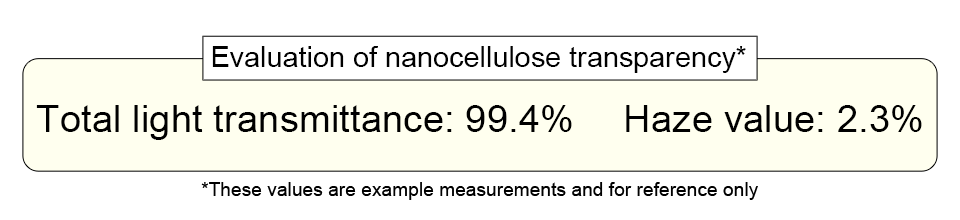

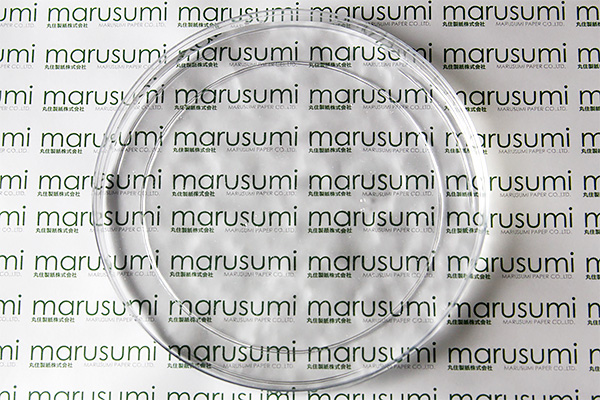

- High transparency

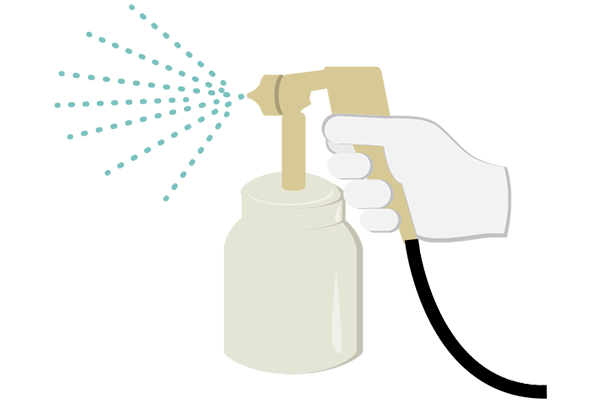

- It is thixotropic

- Functional compound is added to the surface of the cellulose

- Reduced energy use for the fiber-loosening process

Transparency: High level of transparency thanks to our own chemical processing method (CNF concentration: 1.0wt%)

Thixotropy: Gel that can be sprayed and won’t drip (CNF concentration: 0.5wt%, 1.0wt%)

Fluidity: Flows like liquid (CNF concentration 0.5wt%)

Viscosity: Gel that won’t drip even if turned upside down (CNF concentration 1.0wt%)

Nanocellulose uses

We will continue to develop new ways to use the nanocellulose by taking advantage of its highly transparent and thixotropic characteristics so that it can be applied to a wide variety of fields.

Cosmetic products

Cosmetic products Paint materials

Paint materials Optical film

Optical film Automobiles

Automobiles

Cosmetic products

Cosmetic products Paint materials

Paint materials Optical film

Optical film Automobiles

Automobiles